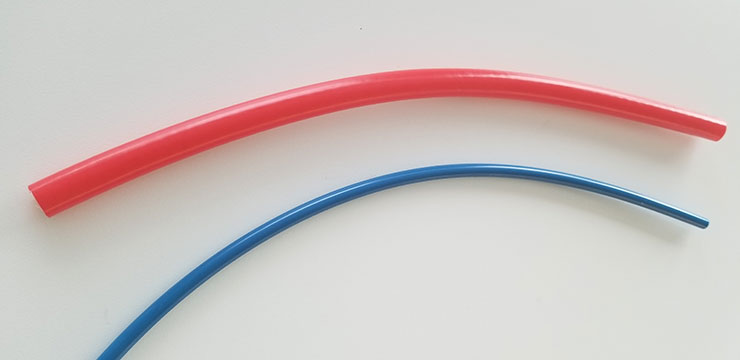

Pneumatic systems are widely used in various industries, such as automation, food and beverage, and packaging, due to their simplicity, efficiency, cleanliness, and versatility. These systems rely on hoses to transport compressed air from the compressor to the devices that utilize it.

However, pneumatic hoses are susceptible to failure over time, just like any other mechanical component. It is crucial to understand the types of failures that can occur and how to prevent them. Here are some of the most common types of pneumatic tube failure and their preventive measures.

Abrasion: Abrasion happens when the hose rubs against another surface, causing it to wear out. Friction between the hose and other components, such as fittings or machinery, can also lead to abrasion. To prevent this, consider using abrasion-resistant hoses, protective sleeves, or install the hose in a way that minimizes contact with other components.

Kinking: Kinking occurs when a hose bends too sharply, resulting in collapsing or forming a permanent bend. This can restrict airflow, damage the hose, and cause pressure loss through leaks. To prevent kinking, ensure proper installation with gradual bends and avoid sharp angles. Each hose has a minimum bending diameter, and bends tighter than recommended can lead to kinks. If a sharp bend is necessary, consider using a female-to-female elbow or installing a swivel joint.

Crushing: When a hose is compressed or flattened by vacuum or the weight of other components, it can become crushed. This can damage the hose, restrict airflow, and lead to leaks due to fatigue caused by repeated events. To prevent crushing, ensure the hose is installed in a way that minimizes contact with heavy components like machinery or vehicles. Protective sleeves or routing the hose to reduce external pressure can also be considered.

Chemical Damage: Chemical damage occurs when a hose is exposed to chemicals that degrade its polymer. This can weaken the hose, causing cracks, brittleness, leaks, or failure. To prevent chemical damage, use hoses resistant to the specific chemicals present in your environment. If the hose must be exposed to chemicals, ensure regular cleaning and maintenance.

Aging: Over time, pneumatic tubes can degrade due to exposure to sunlight, heat, or moisture. Aging causes the hose to become brittle, lose elasticity, and develop cracks, leading to leaks or failure. To prevent aging, consider using hoses designed for outdoor use or those with UV-resistant properties. Store hoses in a cool, dry place, and avoid direct sunlight or heat exposure.

Understanding the types of pneumatic tube failure and how to prevent them is vital for maintaining the efficiency and reliability of your pneumatic system. By selecting the appropriate hose, installing it correctly, and performing regular maintenance, you can minimize the risk of failure and ensure optimal performance. Additionally, conducting routine inspections, testing, and timely replacement of worn-out hoses will help identify potential failures before they occur, saving time, money, and effort in the long run.